Key Takeaways

- Hydraulic cylinders are crucial in various industries, providing the force needed to move heavy loads.

- Different hydraulic cylinders are used for different applications, each with unique benefits and drawbacks.

- Maintaining and troubleshooting hydraulic cylinders can extend their life and improve performance.

- Innovative designs and materials are constantly improving hydraulic cylinder efficiency and capabilities.

The Role of Hydraulic Cylinders in Modern Machinery

These are essential components in the machinery that power various industries. They convert hydraulic energy into mechanical force, enabling heavy lifting, moving, and controlling components. This functional transformation is critical for the diverse needs of modern industry, from building skyscrapers to harvesting crops. The massive and powerful machinery used in construction, agriculture, and manufacturing industries heavily relies on hydraulic cylinders for their robust and reliable performance.

The adaptability and strength of hydraulic cylinders make them indispensable in these fields. Whether driving the boom of an excavator digging through tough terrain or operating the press in a manufacturing plant, hydraulic cylinders ensure the machinery performs as required. Their ability to exert tremendous force, maintain precise control, and work reliably under harsh conditions underscores their importance in keeping industrial applications running smoothly and effectively.

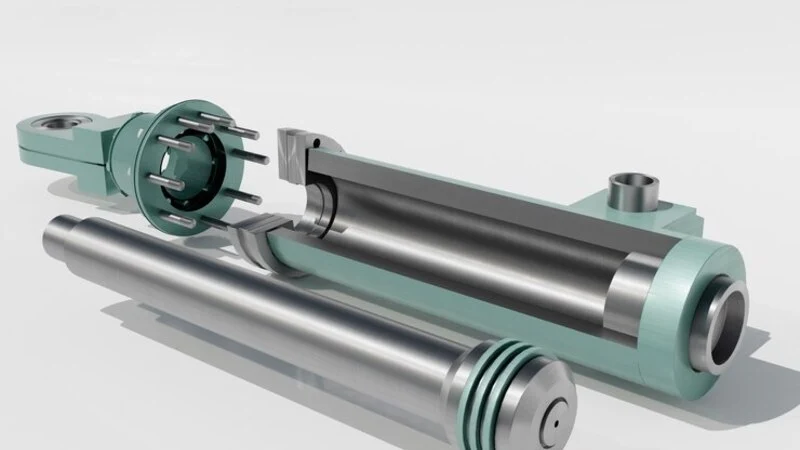

Types of Hydraulic Cylinders

There are several types of hydraulic cylinders, each suited for specific tasks. Their versatility in design allows them to be optimized for different environments and mechanical requirements. Understanding the types of hydraulic products and their applications can help select the most appropriate cylinder for a particular need.

- Single-acting cylinders: These cylinders exert force in one direction and return to their original position through an external force or a spring. They are commonly found in applications where only one direction of force is needed, such as in lifting mechanisms where cylinders raise a load while gravity assists in returning it.

- Double-acting cylinders: These cylinders provide force in both directions, allowing for more versatile applications. Double-acting cylinders are crucial in operations where pushing and pulling are required. For example, double-acting cylinders in hydraulic presses move the press ram upwards and downwards, providing precise control over operations.

- Telescopic cylinders: These multi-stage cylinders can extend longer, making them ideal for limited-space applications. Telescopic cylinders are particularly useful in dump trucks and construction equipment, where they provide the necessary height and reach by extending multiple stages to achieve a significant distance.

Maintenance and Troubleshooting

Regular maintenance of them can prevent common issues such as leaks, corrosion, and wear. Proper maintenance practices are essential to ensure the longevity and functionality of the cylinders. This includes checking for oil cleanliness, inspecting seals, and ensuring proper alignment.

Leaks, the most common problem, can be identified by inspecting seals and connections for signs of oil. Corrosion can be prevented by keeping hydraulic fluid and components clean and using adequate lubricants. When problems occur, troubleshooting involves examining the cylinder for physical damage, checking hydraulic fluid levels, and testing for pressure issues.

Innovations in Hydraulic Cylinders

Advancements in materials and technology are leading to more efficient and durable hydraulic cylinders. Innovations address current challenges and push the boundaries of what these mechanical components can achieve. For instance, new composite materials reduce weight and increase strength, enhance performance, and reduce the operational load on machinery.

Furthermore, sensor technology enhances hydraulic systems by improving fault detection and operational efficiency. Sensors integrated into hydraulic cylinders can provide real-time data on position, load, and temperature, offering valuable preventive maintenance and performance optimization insights. These innovations ensure that hydraulic systems can meet the growing demands of modern industries, enabling smarter, more responsive, and more reliable operations.

Safety and Hydraulic Cylinders

When maintained and used correctly, hydraulic systems can significantly improve workplace safety. Properly functioning hydraulic cylinders reduce the risk of equipment failure, leading to accidents and downtime. Safety is a paramount concern in industrial operations, and hydraulic systems play a vital role.

Ensuring safe operation includes regular inspections, adhering to operational guidelines, and training personnel on proper use. This involves understanding the limits of the equipment, recognizing signs of wear or other issues, and taking appropriate actions before problems escalate. Reliable hydraulic cylinders, with their consistent performance, are essential in maintaining a safe working environment.

To ensure safe operation, it’s essential to follow manufacturer guidelines and industry best practices. This involves technical maintenance and operational protocols. Proper training, regular drills, and comprehensive safety checks can prevent accidents and enhance the efficiency of hydraulic machinery.

Conclusion

Hydraulic cylinders are critical in many applications, from lifting heavy loads on construction sites to precisely controlling factory machinery. Their ability to convert hydraulic energy into powerful mechanical forces is unmatched, making them indispensable in modern industry.

Understanding the various types of them, maintaining them properly, and keeping up with innovations can ensure these powerful components continue to perform efficiently and safely. Reliable hydraulic cylinders can enhance productivity and safety, making them crucial in today’s industrial environments. As industries evolve, so do the requirements and capabilities of hydraulic systems, ensuring they remain at the forefront of technological advancement and practical application.